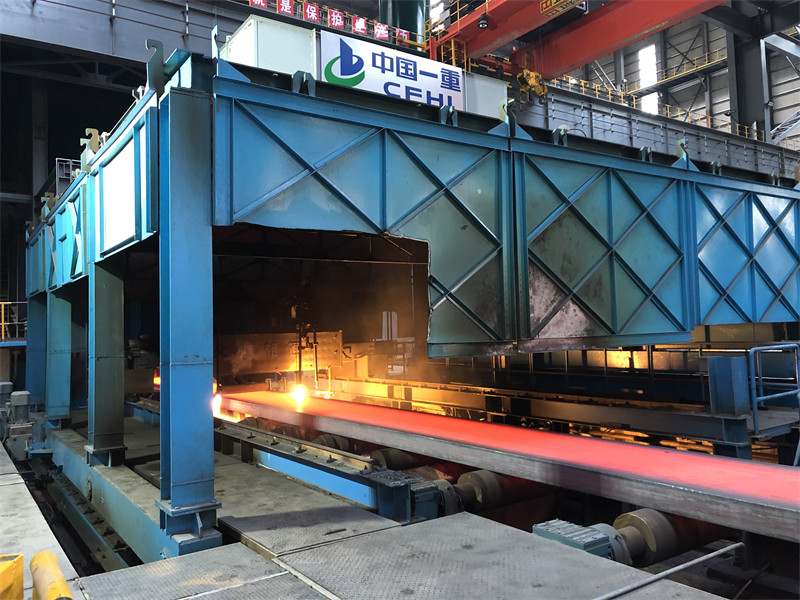

In March, there was good news from the steelmaking business unit! After multiple demonstrations and optimizations of the process by the technical research and development team, special steel 2205, 321, and 310S have successfully achieved pilot production.

On February 16th, under the execution and control of key processes by the R&D and management teams, the company successfully achieved 6-furnace production of duplex stainless steel 2205; On March 1st, heat-resistant steel 310S successfully achieved 11 heats of production; On March 9th, the hot strength steel grade 321 successfully achieved four heats of production. The three steel grades produced in this pilot production have excellent quality and meet customer needs. This is another important breakthrough in the intelligent manufacturing of high-end stainless steel products by the Steelmaking Business Unit!

Among them, 321, as a hot strength steel, has high temperature stress rupture performance and high temperature creep resistance, and can be widely used in industries such as petrochemical, electric power, bridges, and automobiles; Duplex stainless steel 2205 has high strength and corrosion resistance, and can be widely used in fields such as chemical equipment and offshore chemical transportation tanks, coastal bridge construction, guardrails, lamp columns, and foundation construction; 310S is a heat-resistant steel that can withstand repeated heating below 1035 ℃, and is used in industrial furnaces, preheating devices, heaters, reboilers, and automotive exhaust purification devices.

The successful pilot production of special steel has laid a solid foundation for Shengyang Group to further increase its market share in the high-end stainless steel market. Centering on the strategy of strengthening the city with advanced industries, Shengyang Group will follow the current situation, take the market as the guide, overcome the "choke" technology and key common technologies, and inject strong momentum into the industrial development of Linyi City.

2023-03-20

2023-03-20 browse:5383

browse:5383

Mail:xcb@sunyon.cn

Mail:xcb@sunyon.cn address:Shengyang Circulation Industrial Park, Luozhuang·Fuzhuang Office, Linyi, Shandong

address:Shengyang Circulation Industrial Park, Luozhuang·Fuzhuang Office, Linyi, Shandong

鲁ICP备13027174号-2

鲁ICP备13027174号-2